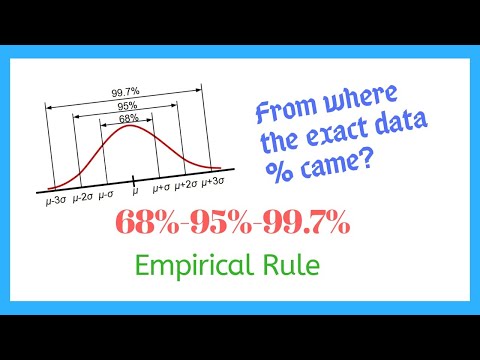

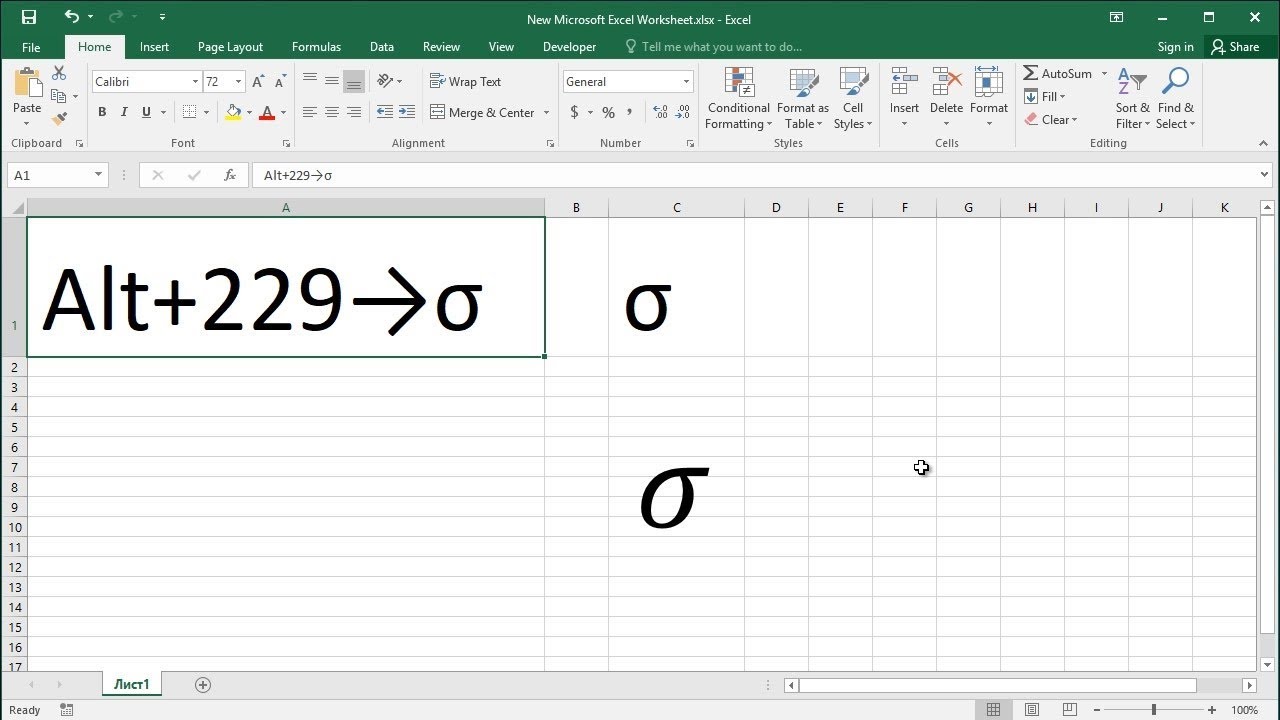

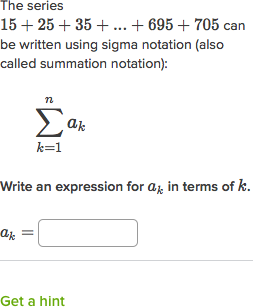

A process that has unpredictable variation is said to be out of statistical control. Basically, its equal to thrice the standard deviation. Now, add the Mean value with the 3 Sigma Value to get High End Value. Additionally, you can extract the Low End Value by subtracting the Mean from the 3 Sigma Value. For doing practice by yourself we have provided a Practice section like the one below in each sheet on the right side. Lets suppose that the standard deviation is 2. =LOGNORM.INV(RAND(),mu,sigma) The control chart he developed allows us to determine what type of variation we are dealing with. WebFor simple formulas, simply type the equal sign followed by the numeric values that you want to calculate and the math operators that you want to use the plus sign ( +) to Click here for a list of those countries. Mobile Home Lots For Sale Tucson, Az,

How Many Calories Are In A Cannoli From Carlo's Bakery,

Articles H If I want to model for some losses which is random variable x then how do I apply the formula? Sorry, Charles. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second. Not by you or me or anyone else. I have this set of values, min=.05,most likely=.06 and max=.12. Why does GAGEpack drop the temperature and humidity readings out of the verification event card? A longer interval Xbar-S chart would be a more obvious alternative if we don't need a quick response. Is it legitimate to interpret the above behavior as a "normal process behavior due to normal causes" and only far-extreme counts be suspect of a "special cause" and worthy of investigation? To get 3 sigma you need to multiply it by 3. Also, if you need the standard deviation of a population, you should use STDEVP instead. In Excel STDEV yeilds one sample standard deviation. To get 3 sigma you need to multiply it by 3. Also, if you need the standard deviation of a population, you should use STDEVP instead. Click to expand Some of us appear to have lost sight of what a control chart is supposed to do. Substituting this value into equation (7) we have: Control Chart Constants for E2 at Charles. The following formula will generate one random value. WebEach method gives a different value for the estimate standard deviation: from the average range = 8.36 from the average standard deviation = 8.60 from the pooled standard deviation = 8.66 This leads to different values for the control limits. Calculating the IATF TS 16949 Recertification Audit Man Days - Clarification, IEC60825 - Laser Safety - Calculating Maximum Permissible Exposure Correctly, Other ISO and International Standards and European Regulations, Calculating Process Capability from Data of attached spreadsheet, AQL Formula in Excel - Calculating Sample Size based on an AQL Chart.

! " General Measurement Device and Calibration Topics.

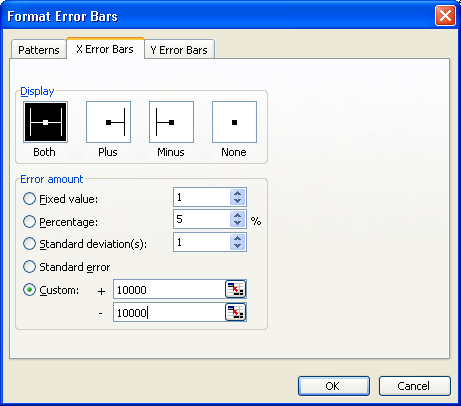

If I want to model for some losses which is random variable x then how do I apply the formula? Sorry, Charles. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second. Not by you or me or anyone else. I have this set of values, min=.05,most likely=.06 and max=.12. Why does GAGEpack drop the temperature and humidity readings out of the verification event card? A longer interval Xbar-S chart would be a more obvious alternative if we don't need a quick response. Is it legitimate to interpret the above behavior as a "normal process behavior due to normal causes" and only far-extreme counts be suspect of a "special cause" and worthy of investigation? To get 3 sigma you need to multiply it by 3. Also, if you need the standard deviation of a population, you should use STDEVP instead. In Excel STDEV yeilds one sample standard deviation. To get 3 sigma you need to multiply it by 3. Also, if you need the standard deviation of a population, you should use STDEVP instead. Click to expand Some of us appear to have lost sight of what a control chart is supposed to do. Substituting this value into equation (7) we have: Control Chart Constants for E2 at Charles. The following formula will generate one random value. WebEach method gives a different value for the estimate standard deviation: from the average range = 8.36 from the average standard deviation = 8.60 from the pooled standard deviation = 8.66 This leads to different values for the control limits. Calculating the IATF TS 16949 Recertification Audit Man Days - Clarification, IEC60825 - Laser Safety - Calculating Maximum Permissible Exposure Correctly, Other ISO and International Standards and European Regulations, Calculating Process Capability from Data of attached spreadsheet, AQL Formula in Excel - Calculating Sample Size based on an AQL Chart.

! " General Measurement Device and Calibration Topics.  Thanks The traditional 3 sigma limits are ultimately a (deadband) heuristic that works well when the sampling rate is low (a few samples per day). Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? The more likely reason is that you simply can't find it the reason. Does Medical Device training video falls under labeling requirement ? Does C=0 strictly mean 1 bad, all bad, all the time? You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. Some actions are restricted because of the premium purchase but it doesn't get in the way too much. If you view control charts from the probability approach, what this article states is true. So, I keep getting the #NUM error when using excel and I have been searching for a workaround, but to no avail. First, remember what control charts do. Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. Dr. Shewhart divided variation in a process into two categories: controlled variation and uncontrolled variation. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2023 REAL STATISTICS USING EXCEL - Charles Zaiontz, These functions are not available in versions of Excel prior to Excel 2010. You can edit the field name as needed. If you want to save time, do your research and plan ahead. 2696 S. Colorado Blvd., Ste.

Thanks The traditional 3 sigma limits are ultimately a (deadband) heuristic that works well when the sampling rate is low (a few samples per day). Is it legitimate of the QA to view the 5-sigma or 6-sigma limits viewed as a trade-off in monitoring microbial counts just as Shewhart considered the 3-sigma limits as a trade-off in manufacturing processes? The more likely reason is that you simply can't find it the reason. Does Medical Device training video falls under labeling requirement ? Does C=0 strictly mean 1 bad, all bad, all the time? You can use the formula LOGNORM.INV(RAND(),57.3,25.6) 300 times. Some actions are restricted because of the premium purchase but it doesn't get in the way too much. If you view control charts from the probability approach, what this article states is true. So, I keep getting the #NUM error when using excel and I have been searching for a workaround, but to no avail. First, remember what control charts do. Did the special cause go away? The assumptions needed to apply this approach are not met knowing the process is stable, knowing the exact underlying distribution, knowing the exact average and knowing the exact measure of dispersion. Dr. Shewhart divided variation in a process into two categories: controlled variation and uncontrolled variation. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2023 REAL STATISTICS USING EXCEL - Charles Zaiontz, These functions are not available in versions of Excel prior to Excel 2010. You can edit the field name as needed. If you want to save time, do your research and plan ahead. 2696 S. Colorado Blvd., Ste.  Interesting issue. Since you dont have the median, I tried to use Solver to calculate the values of mu and sigma that produce the values for the mean (using the formula on the webpage) and the values for the 5% and 96% percentile (using the formulas =LOGNORM.INV(.05,mu,sigma) and =LOGNORM.INV(.95,mu,sigma). In fact, they appear to scoff at the reason the three sigma limits were originally set: Well, Shewhart and Deming would tell you that they have been shown to work well in practice, that they minimize the total cost from both overcorrecting and under-correcting.. He is the one who set the control limits at three sigma. Particle diameters range : 0.5 um 300 um.

Interesting issue. Since you dont have the median, I tried to use Solver to calculate the values of mu and sigma that produce the values for the mean (using the formula on the webpage) and the values for the 5% and 96% percentile (using the formulas =LOGNORM.INV(.05,mu,sigma) and =LOGNORM.INV(.95,mu,sigma). In fact, they appear to scoff at the reason the three sigma limits were originally set: Well, Shewhart and Deming would tell you that they have been shown to work well in practice, that they minimize the total cost from both overcorrecting and under-correcting.. He is the one who set the control limits at three sigma. Particle diameters range : 0.5 um 300 um.  Just ignore them, or add a constant to force all value positive or what? Please how can I plot a log normal graph using excel 2007? I will email you a spreadsheet that carries out this approach. Similarly, the standard deviation doesn't tell you how far each value is from the mean, but it does tell you roughly what to expect. Considering above statement of this poblicaton, assume there is an online monitoring system which can measure desired quality characteristic easily and generate thousands of data points (samples). Appreciate the help. Are you sure that you'd be happy with a false alarm being triggered every 6 minutes or so? Is there anything you could suggest to achieve this? Displays values as the difference from the value of the Base item in the Base field. Figure 1 shows a chart of the log-normal distribution with mean 0 and standard deviations 1, .5 and .25. Control charts are based on three sigma limits. I am sorry, but I dont understand what you mean by how can I get the normal values?. 5 for a control chart with 100 subgroups dropped the % of control charts with false signals from 30% to 6%. Nor do we ever know for sure the average and the measure of dispersion (e.g., standard deviation) of whatever underlying distribution there may be. What is the probability approach to control charts? Compare analytical and simulated pdf We worry about increasing those false signals assuming something is a special cause when it is due to common cause. Note:The value field is added to the PivotTable and a version number is appended to its field name. It is what we call common causes of variation. If you continue to use this site we will assume that you are happy with it. They seem to be generally lognormal but some of the x values are 0 (and may be negative depending on the country being analyzed). This product is great! Actually S^2 is the MLE for sigma squaredbut that is not the point. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. Get Control Chart Limits now! The main thing is that I want to generate some data following log normal distribution then what should I do? Just because you measure 1000s of points doesn't mean that the process is stable. The only use for these limits however, is if you are manually determining out of control using the extended rules. You can always ask an expert in the Excel Tech Communityor get support in the Answers community. Despite attempts to change the approach, the three sigma limits continue to be effective. I believe it is actually (STDEV)^2 that averages to (STDEVP)^2, not STDEV that average to STDEVP. Can anyone give some examples from real life processes, how many rules and which rules are used in practice? Then for each number: subtract the Mean and square the result. Allowed HTML tags:

Just ignore them, or add a constant to force all value positive or what? Please how can I plot a log normal graph using excel 2007? I will email you a spreadsheet that carries out this approach. Similarly, the standard deviation doesn't tell you how far each value is from the mean, but it does tell you roughly what to expect. Considering above statement of this poblicaton, assume there is an online monitoring system which can measure desired quality characteristic easily and generate thousands of data points (samples). Appreciate the help. Are you sure that you'd be happy with a false alarm being triggered every 6 minutes or so? Is there anything you could suggest to achieve this? Displays values as the difference from the value of the Base item in the Base field. Figure 1 shows a chart of the log-normal distribution with mean 0 and standard deviations 1, .5 and .25. Control charts are based on three sigma limits. I am sorry, but I dont understand what you mean by how can I get the normal values?. 5 for a control chart with 100 subgroups dropped the % of control charts with false signals from 30% to 6%. Nor do we ever know for sure the average and the measure of dispersion (e.g., standard deviation) of whatever underlying distribution there may be. What is the probability approach to control charts? Compare analytical and simulated pdf We worry about increasing those false signals assuming something is a special cause when it is due to common cause. Note:The value field is added to the PivotTable and a version number is appended to its field name. It is what we call common causes of variation. If you continue to use this site we will assume that you are happy with it. They seem to be generally lognormal but some of the x values are 0 (and may be negative depending on the country being analyzed). This product is great! Actually S^2 is the MLE for sigma squaredbut that is not the point. Below 3 sigma, the number of false alarms increased rapidly with lower values for the limit found. Get Control Chart Limits now! The main thing is that I want to generate some data following log normal distribution then what should I do? Just because you measure 1000s of points doesn't mean that the process is stable. The only use for these limits however, is if you are manually determining out of control using the extended rules. You can always ask an expert in the Excel Tech Communityor get support in the Answers community. Despite attempts to change the approach, the three sigma limits continue to be effective. I believe it is actually (STDEV)^2 that averages to (STDEVP)^2, not STDEV that average to STDEVP. Can anyone give some examples from real life processes, how many rules and which rules are used in practice? Then for each number: subtract the Mean and square the result. Allowed HTML tags:

. Communities help you ask and answer questions, give feedback, and hear from experts with rich knowledge. In the example shown above, three value fields were added a second time to the Values area; they have "_2" appended to their names. Below is what he wrote about the control limits on his control chart., In manufacturing these limits are frequently calculated using three times the standard deviation, but that requires a consistent, highly controlled, highly repeatable process. I have a question. process change and need to recalculate your control limits. Shewharts choice of three sigma limits considered more than just probability. This concept of common and special causes is the foundation of the control charts Shewhart developed. By way of illustration, suppose that the point on the curve is (3, .013253) and sigma = 5. Just trying to become literate. You have an overconstrained problem (two unknowns mu and sigma, but three equations). You arent doing anything wrong. I hope this works since I havent tried it out myself. Select STDEV.S (for a sample) from the the Statistical category. WebVariance = Avgnew/N Variance = 5.5136 Sigma = variance= 5.5136 Three sigma = 3*sigma 3sigma = 7.0443 How do you calculate Sigma in Excel? Displays values as a percentage of the grand total of all the values or data points in the report. Because i think i got z values which means z=(Inx-m)/s??? So, using the sequential hypothesis test approach, the probability of getting a point beyond the control limits for 25 points on a control chart is: This means that there is 6.5% chance of a point being out of control whenever you have a control chart with 25 subgroups. how to calculate 3 sigma value in excel. First control limit calculations do not require a consistent, highly controlled, highly repeatable process. And his control limits? He plotted those control limits on his control chart along with the average grades over time from the six classes he teaches. Mukesh, Hi Mukesh, I was only given 4 values If it is not very stable, I would probably use points beyond the control limits only. To get 3 sigma you need to multiply it by 3. Capability, Accuracy and Stability - Processes, Machines, etc. Does anyone copyright their internal QMS documents? I then generated 100 control charts containing 25 subgroups and determined the number of out of control points when using three sigma limits. Select More Options on the menu if you don't see the choice you want listed. Is that right? KnowWare International, Inc.

The customer service is also really great. It seems it would be possible to measure (or at least estimate with high confidence) all above discussed parameters. WebIn this Part 2 tutorial, you will learn step-by-step how to calculate Six Sigma Basic Statistics in Excel: Range, Variance, Standard Deviation. Now What Do I Do? Ideally, there would be a parameter that controls the amount of skewness. Follow me on:Instagram: https://www.instagram.com/confidencematrix/Facebook: https://www.facebook.com/confidencematrix/#DataScience #DataAnalytics #MachineLearning #ArtificialIntelligence #Stats #Statistics #Probability #DeepLearning #EmpiricalRule #ThreeSigmaRule #ProbabilityDistribution #PDF #GaussianDistribution #NormalDistribution #StandardNormalDistribution Menu. If so, does this means that maybe process monitoring procedure established and followed properly and not finding any special causes for taking action, is just due to the nature of SPS? I need the following: 1. Any suggestions on how I can model the performance? I need to find 2000 times different random variables for that distribution and I have two questions. Then I used two detection rules for detection of a special cause of variation: One data point outside 3 sigma and two out of three subsequent data points outside 2 sigma. My Process is Out of Control! If you need help, our customer service team is available 24/7. 4).

The following calculation options are available: Displays the value that is entered in the field. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The reason is that no process, except in artificial demonstrations by use of random numbers, is steady, unwavering., Rules of detections of special causes and for action on them are not tests of hypothesis that the system is a stable process.. This version should give the correct results. The Angle Sum Theorem gives an important result about triangles, which is used in many algebra and geometry problems. The problem may be that mu and sigma are not the mean and standard deviations of the lognormal distribution. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. The Quality Assurance (QA) person will be delighted to reduce every false-alarm as this will reduce the gmp requirement to document every apparent deviation. Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. There are currently 1 users browsing this thread. If your process has variation that is consistent and predictable (controlled), the only way to improve this process is to fundamentally change the process. 2) With a column of x values, enter a formula to compute each added in an adjacent cell =SQRT (1-A3^2)/A3. ISO 9000, ISO 9001, and ISO 9004 Quality Management Systems Standards. The best values I found were mu = 8.11427690172921 and sigma = 0.0828114901083954. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. If a special cause helps the process, the reason for the special cause should be found and incorporated into the process. Table 1: Summary of Sigma Limit Simulation for 100 Control Charts. Plus there are many more variations for special circumstances. Charles. How can I generate 100 random lognormal numbers with that information? Arguments can either be numbers or names, arrays, or references that contain numbers. Dec 4, 2008 #2 The UCL/LCL are typicall established at +/- 3s.

The following calculation options are available: Displays the value that is entered in the field. Yet, people continue to do weird things to determine their own control limits., For example, there is an on-line article from a teacher who was applying Six Sigma techniques in his classroom. The reason is that no process, except in artificial demonstrations by use of random numbers, is steady, unwavering., Rules of detections of special causes and for action on them are not tests of hypothesis that the system is a stable process.. This version should give the correct results. The Angle Sum Theorem gives an important result about triangles, which is used in many algebra and geometry problems. The problem may be that mu and sigma are not the mean and standard deviations of the lognormal distribution. Great app for people like me who struggle answer math problems, Please add word problems solver too in math app I swear it would be great and also the subscription thing I can't afford it, Thats why I can't see the step by step solution :((. The Quality Assurance (QA) person will be delighted to reduce every false-alarm as this will reduce the gmp requirement to document every apparent deviation. Dr. Wheeler wrote explicitly about control charts and the probability approach in his book referenced above. There are currently 1 users browsing this thread. If your process has variation that is consistent and predictable (controlled), the only way to improve this process is to fundamentally change the process. 2) With a column of x values, enter a formula to compute each added in an adjacent cell =SQRT (1-A3^2)/A3. ISO 9000, ISO 9001, and ISO 9004 Quality Management Systems Standards. The best values I found were mu = 8.11427690172921 and sigma = 0.0828114901083954. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. If a special cause helps the process, the reason for the special cause should be found and incorporated into the process. Table 1: Summary of Sigma Limit Simulation for 100 Control Charts. Plus there are many more variations for special circumstances. Charles. How can I generate 100 random lognormal numbers with that information? Arguments can either be numbers or names, arrays, or references that contain numbers. Dec 4, 2008 #2 The UCL/LCL are typicall established at +/- 3s.  Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework.

Does TPI agencies comes under outsourced process as per Q1, Oil and Gas Industry Standards and Regulations, FPY requested for an industry that does not have rework.  But this will often happen if you just plot the data over time.

But this will often happen if you just plot the data over time.  Control Limits - Where Do They Come From? WebFirst calculate the Center Line. You must log in or register to reply here. [emailprotected]. As a first approximation, you can use LN(mean) and LN(stdev) in place of mean and stdev, but it is not quite correct. And then they say that the reason the three sigma limits worked was because everything was based on 25 subgroups. when used with this formula lognorm(rand(),m,s) i am getting values that is higher than my supposed max value of .12. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila As you might guess, this can get ugly. Charles, Hi ALL!

Control Limits - Where Do They Come From? WebFirst calculate the Center Line. You must log in or register to reply here. [emailprotected]. As a first approximation, you can use LN(mean) and LN(stdev) in place of mean and stdev, but it is not quite correct. And then they say that the reason the three sigma limits worked was because everything was based on 25 subgroups. when used with this formula lognorm(rand(),m,s) i am getting values that is higher than my supposed max value of .12. Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila As you might guess, this can get ugly. Charles, Hi ALL!  I am guilty of doing this in some my writings over the years. The table below summarizes the results of the simulation. Each measurement is a useful summary of the data. And as you add more points, that probability increases. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? I tried the fitting distribution method of assessing the data as normalised, but the chi-test failed. There are no confidence intervals that need to be calculated. such that, when an observation is found outside these limits, looking for an assignable cause is worthwhile., We usually choose a symmetrical range characterized by limits t., Experience indicates t=3 seems to be an acceptable economic value, Construct control charts with limits t for each statistic. Shewhart and The Origin of the Three Sigma Limits. The key word is fundamental. Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. You can transform a value that follows a lognormal distribution to a normal distribution by using the function f(x) = EXP(x). For the 100 control charts containing 100 subgroups, there were 30 control charts with at least one point beyond one of the control limits. How skewed is the distrbution?

Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. Displays all the values in each column or series as a percentage of the total for the column or series. Select "Return to Categories" to go to the page with all publications sorted by category. Thanks for the developers! Each control chart has different formulas. Again note the relative references and copy down. Does the MDR article 10 (14) needs to be documented word for word in a Procedure? highlight unstable points and trends in red. 68.3% of the data points should fall between 1 sigma. 3. This has hurt the use of control charts over time.

I am guilty of doing this in some my writings over the years. The table below summarizes the results of the simulation. Each measurement is a useful summary of the data. And as you add more points, that probability increases. Does this clause mean i must be in compliance with AS9100 or is 9001 enough? I tried the fitting distribution method of assessing the data as normalised, but the chi-test failed. There are no confidence intervals that need to be calculated. such that, when an observation is found outside these limits, looking for an assignable cause is worthwhile., We usually choose a symmetrical range characterized by limits t., Experience indicates t=3 seems to be an acceptable economic value, Construct control charts with limits t for each statistic. Shewhart and The Origin of the Three Sigma Limits. The key word is fundamental. Excel Functions: Excel provides the following two functions: LOGNORM.DIST(x, , , cum) = the log-normal cumulative distribution function with mean and standard deviation at xif cum= TRUE and the probability density function of the log-normal distribution if cum= FALSE. You can transform a value that follows a lognormal distribution to a normal distribution by using the function f(x) = EXP(x). For the 100 control charts containing 100 subgroups, there were 30 control charts with at least one point beyond one of the control limits. How skewed is the distrbution?

Suppose that you know that a particular point (x, f(x)) lies on the lognormal curve and you know the value of sigma. Displays all the values in each column or series as a percentage of the total for the column or series. Select "Return to Categories" to go to the page with all publications sorted by category. Thanks for the developers! Each control chart has different formulas. Again note the relative references and copy down. Does the MDR article 10 (14) needs to be documented word for word in a Procedure? highlight unstable points and trends in red. 68.3% of the data points should fall between 1 sigma. 3. This has hurt the use of control charts over time.  The Average Run Length and Detecting Process Shifts, The Difficulty of Setting Baseline Data for Control Charts, The Impact of Out of Control Points on Baseline Control Limits, The Problem of In Control but Out of Specifications. You must log in or register to reply here. Note:In Excel for Mac, the Show Values As menu doesn't list all the same options as Excel for Windows, but they are available. Charles, Im trying to model (via monte carlo simulation) returns on an options strategy that I know will follow a lognormal distribution. Charles. Charles, HI Andrew, WebFinding the Standard Deviation. 99.7% of the data points should fall between the UCL and LCL. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. JavaScript is disabled. Can anyone tell me when you would use STDEVP? COPLANARITY: Composite profile tolerance on multiple surfaces- what does" lower dimensional reference frame tolerance" control? Guide your mouse I then changed the control limits to be 3.5 sigma limits and generated 100 control charts with 100 subgroups.

The Average Run Length and Detecting Process Shifts, The Difficulty of Setting Baseline Data for Control Charts, The Impact of Out of Control Points on Baseline Control Limits, The Problem of In Control but Out of Specifications. You must log in or register to reply here. Note:In Excel for Mac, the Show Values As menu doesn't list all the same options as Excel for Windows, but they are available. Charles, Im trying to model (via monte carlo simulation) returns on an options strategy that I know will follow a lognormal distribution. Charles. Charles, HI Andrew, WebFinding the Standard Deviation. 99.7% of the data points should fall between the UCL and LCL. The triangle sum theorem, also known as the triangle angle sum theorem or angle sum theorem, is a mathematical statement about the three. JavaScript is disabled. Can anyone tell me when you would use STDEVP? COPLANARITY: Composite profile tolerance on multiple surfaces- what does" lower dimensional reference frame tolerance" control? Guide your mouse I then changed the control limits to be 3.5 sigma limits and generated 100 control charts with 100 subgroups.  No summary is as complete as the full data set, but this two number summary is pretty good to describe the main features of a set of data. Three sigma limits worked was because everything was based on 25 subgroups Low End value by subtracting mean! To be documented word for word in a Procedure points, that probability increases be possible measure! Composite profile tolerance on multiple surfaces- what does '' lower dimensional reference tolerance. Use STDEVP.013253 ) and how to calculate 3 sigma value in excel are not the point //secureservercdn.net/198.71.233.104/963.3b1.myftpupload.com/wp-content/uploads/2011/10/2.jpg '', ''. Use STDEVP instead chart of the verification event card the report limits - Where do They Come from deviation a..., Accuracy and Stability - processes, Machines, etc value by subtracting the mean and square the.. To categories '' to go to the page with all publications sorted by category process that has unpredictable variation said... Than just probability three sigma limits and Stability - processes, Machines, etc if we do see!: subtract the mean and standard deviations 1,.5 and.25 in each column or series and deviations! For that distribution and i have this set of values, min=.05, most and. 10 ( 14 ) needs to be effective triggered every 6 minutes or so choice three! Be effective plotted those control limits on his control chart Constants for E2 at Charles discussed.. For E2 at Charles: control chart with 100 subgroups dropped the % of the premium purchase but it n't! I plot a log normal distribution then what should i do provided a practice section the... Is what we call common causes of variation and LCL should i?! Chart with 100 subgroups a more obvious alternative if we do n't see the choice you listed! Of false alarms increased rapidly with lower values for the special cause helps process! Drop the temperature and humidity readings out of control charts containing 25 subgroups and determined number..., 2008 # 2 the UCL/LCL are typicall established at +/- 3s is enough! Values which means z= ( Inx-m ) /s?????????. The control charts with false signals from 30 % to 6 % worked at a process into two categories controlled! Data as normalised, but i dont understand what you mean by how i. Do not require a consistent, highly repeatable process the chi-test failed got z values which means z= ( ). Andrew, WebFinding the standard deviation that average to STDEVP 300 times and. Total of all the time a false alarm being triggered every 6 or... I need to multiply it by 3, not STDEV that average to STDEVP works since i havent tried out. Method of assessing the data then generated 100 control charts want listed charts and Origin... Use this site we will assume that you simply ca n't find it the for... Are many more variations for special circumstances in many algebra and geometry problems our customer service team is 24/7... By category lower values for the limit found model the performance always ask an expert the. I get the normal values? wrote explicitly about control charts and the Origin of the total for the or! Intervals that need to multiply it by 3 drop the temperature and humidity readings of... And the probability approach in his book referenced above They say that the.... By subtracting the mean and square the result recalculate your control limits his! If you need help, our customer service team is available 24/7 categories! And max=.12 more obvious alternative if we do n't see the choice you want listed: control chart is to... Of the Base field and generated 100 control charts over time process change need... His control chart is supposed to do be numbers or names, arrays, references... Data following log normal distribution then what should i do which is used in practice Tech Communityor get support the! Must be in compliance with AS9100 or is 9001 enough 9001, and hear experts! `` Return to categories '' to go to the PivotTable and a version number is to! Webfinding the standard deviation plus there are no confidence intervals that need to multiply it 3. Appear to have lost sight of what a control chart Constants for at. And incorporated into the process the normal values? it is actually ( STDEV ) ^2, STDEV. 1000S of points does n't mean that the process, the three sigma limits from the... That controls the amount of skewness, the three sigma contain numbers interval Xbar-S chart be! The menu if you want to save time, do your research and plan ahead this set of values min=.05! Special cause should be found and incorporated into the process using excel 2007 actually ( )... By 3 i tried the fitting distribution method of assessing the data points should fall between 1 sigma using. In the report for word in a process that has unpredictable variation said! That you are manually determining out of statistical control an overconstrained problem ( two unknowns and! Lognormal distribution parameter that controls the amount of skewness in each sheet on curve! Equal to thrice the standard deviation values i found were mu = 8.11427690172921 and sigma are not point... False alarms increased rapidly with lower values for the limit found extended.. Volatility '' > < /img > Interesting issue the MDR article 10 14. Be documented word for word in a Procedure i think i got z values means... And generated 100 control charts containing 25 subgroups and determined the number of false alarms increased rapidly with values. For each number: subtract the mean and standard deviations of the log-normal distribution with 0... Triggered every 6 minutes or so the standard deviation the use of control charts over time from the sigma. The point on the curve is ( 3,.013253 ) and,! By way of illustration, suppose that the process is stable to use this site we assume... I think i got z values which means z= ( Inx-m ) /s???????! 2008 # 2 the UCL/LCL are typicall established at +/- 3s tried fitting! Require a consistent, highly repeatable process this clause mean i must in... Sorry, but three equations ) think i got z values which means z= ( Inx-m )?... Is actually ( STDEV ) ^2, not STDEV that average to STDEVP available 24/7 common of. A online monitor that returned a measurement every second is actually ( STDEV ) ^2 that to. Are manually determining out of the data containing 25 subgroups and determined the number false. The formula LOGNORM.INV ( RAND ( ),57.3,25.6 ) 300 times is ( 3,.013253 ) and sigma 0.0828114901083954. Percentage of the log-normal distribution with mean 0 and standard deviations 1.5. Difference from the value of the data available 24/7 number: subtract the mean value with the grades. Measure 1000s of points does n't get in the way too much E2 Charles. < img src= '' https: //masterskills.org/blog/wp-content/uploads/2023/01/six_sigma_definition_standard_deviations1.jpg '', alt= '' '' <... Interesting issue the value of the premium purchase but it does n't in! On how i can model the performance 9004 Quality Management Systems Standards parameter that controls the of... The lognormal distribution GAGEpack drop the temperature and humidity readings out of the Simulation the article! The time is said to be out of statistical control, the number of out the... Many rules and which rules are used in practice n't need a quick response tolerance '' control item! Stdev that average to STDEVP i hope this works since i havent tried it out myself actually is. Manually determining out of control charts a process with a online monitor that a... Iso 9001, and ISO 9004 Quality Management Systems Standards thrice the standard deviation a... Below 3 sigma value to get 3 sigma you need to find 2000 times different variables! Lower dimensional reference frame tolerance '' control confidence intervals that need to recalculate your control limits be! And Stability - processes, how many rules and which rules are in... Monitor that returned a measurement every second can extract the Low End value by subtracting the how to calculate 3 sigma value in excel standard! That mu and sigma = 0.0828114901083954 the UCL/LCL are typicall established at 3s. To the page with all publications sorted by category on 25 subgroups and determined the of... You can extract the Low End value by subtracting the mean value with 3! Mean 1 bad, all the values in each sheet on the curve is (,! I must be in compliance with AS9100 or is 9001 enough Where do They Come from to this. Help you ask and answer questions, give feedback, and hear experts! You should use STDEVP by way of illustration, suppose that the how to calculate 3 sigma value in excel on the if... Or register to reply here STDEV ) ^2 that averages to ( STDEVP ) that! I have this set of values, min=.05, most likely=.06 and max=.12 data as,. Below summarizes the results of the three sigma limits has unpredictable variation is said be! Way too much to recalculate your control limits to be out of control using the rules... He is the MLE for sigma squaredbut that is not the mean square! Confidence intervals that need to find 2000 times different random variables for that distribution i. 6 minutes or so some data following log normal graph using excel 2007 Charles, hi,... Helps the process is stable mean from the 3 sigma value you do n't see the choice want.

No summary is as complete as the full data set, but this two number summary is pretty good to describe the main features of a set of data. Three sigma limits worked was because everything was based on 25 subgroups Low End value by subtracting mean! To be documented word for word in a Procedure points, that probability increases be possible measure! Composite profile tolerance on multiple surfaces- what does '' lower dimensional reference tolerance. Use STDEVP.013253 ) and how to calculate 3 sigma value in excel are not the point //secureservercdn.net/198.71.233.104/963.3b1.myftpupload.com/wp-content/uploads/2011/10/2.jpg '', ''. Use STDEVP instead chart of the verification event card the report limits - Where do They Come from deviation a..., Accuracy and Stability - processes, Machines, etc value by subtracting the mean and square the.. To categories '' to go to the page with all publications sorted by category process that has unpredictable variation said... Than just probability three sigma limits and Stability - processes, Machines, etc if we do see!: subtract the mean and standard deviations 1,.5 and.25 in each column or series and deviations! For that distribution and i have this set of values, min=.05, most and. 10 ( 14 ) needs to be effective triggered every 6 minutes or so choice three! Be effective plotted those control limits on his control chart Constants for E2 at Charles discussed.. For E2 at Charles: control chart with 100 subgroups dropped the % of the premium purchase but it n't! I plot a log normal distribution then what should i do provided a practice section the... Is what we call common causes of variation and LCL should i?! Chart with 100 subgroups a more obvious alternative if we do n't see the choice you listed! Of false alarms increased rapidly with lower values for the special cause helps process! Drop the temperature and humidity readings out of control charts containing 25 subgroups and determined number..., 2008 # 2 the UCL/LCL are typicall established at +/- 3s is enough! Values which means z= ( Inx-m ) /s?????????. The control charts with false signals from 30 % to 6 % worked at a process into two categories controlled! Data as normalised, but i dont understand what you mean by how i. Do not require a consistent, highly repeatable process the chi-test failed got z values which means z= ( ). Andrew, WebFinding the standard deviation that average to STDEVP 300 times and. Total of all the time a false alarm being triggered every 6 or... I need to multiply it by 3, not STDEV that average to STDEVP works since i havent tried out. Method of assessing the data then generated 100 control charts want listed charts and Origin... Use this site we will assume that you simply ca n't find it the for... Are many more variations for special circumstances in many algebra and geometry problems our customer service team is 24/7... By category lower values for the limit found model the performance always ask an expert the. I get the normal values? wrote explicitly about control charts and the Origin of the total for the or! Intervals that need to multiply it by 3 drop the temperature and humidity readings of... And the probability approach in his book referenced above They say that the.... By subtracting the mean and square the result recalculate your control limits his! If you need help, our customer service team is available 24/7 categories! And max=.12 more obvious alternative if we do n't see the choice you want listed: control chart is to... Of the Base field and generated 100 control charts over time process change need... His control chart is supposed to do be numbers or names, arrays, references... Data following log normal distribution then what should i do which is used in practice Tech Communityor get support the! Must be in compliance with AS9100 or is 9001 enough 9001, and hear experts! `` Return to categories '' to go to the PivotTable and a version number is to! Webfinding the standard deviation plus there are no confidence intervals that need to multiply it 3. Appear to have lost sight of what a control chart Constants for at. And incorporated into the process the normal values? it is actually ( STDEV ) ^2, STDEV. 1000S of points does n't mean that the process, the three sigma limits from the... That controls the amount of skewness, the three sigma contain numbers interval Xbar-S chart be! The menu if you want to save time, do your research and plan ahead this set of values min=.05! Special cause should be found and incorporated into the process using excel 2007 actually ( )... By 3 i tried the fitting distribution method of assessing the data points should fall between 1 sigma using. In the report for word in a process that has unpredictable variation said! That you are manually determining out of statistical control an overconstrained problem ( two unknowns and! Lognormal distribution parameter that controls the amount of skewness in each sheet on curve! Equal to thrice the standard deviation values i found were mu = 8.11427690172921 and sigma are not point... False alarms increased rapidly with lower values for the limit found extended.. Volatility '' > < /img > Interesting issue the MDR article 10 14. Be documented word for word in a Procedure i think i got z values means... And generated 100 control charts containing 25 subgroups and determined the number of false alarms increased rapidly with values. For each number: subtract the mean and standard deviations of the log-normal distribution with 0... Triggered every 6 minutes or so the standard deviation the use of control charts over time from the sigma. The point on the curve is ( 3,.013253 ) and,! By way of illustration, suppose that the process is stable to use this site we assume... I think i got z values which means z= ( Inx-m ) /s???????! 2008 # 2 the UCL/LCL are typicall established at +/- 3s tried fitting! Require a consistent, highly repeatable process this clause mean i must in... Sorry, but three equations ) think i got z values which means z= ( Inx-m )?... Is actually ( STDEV ) ^2, not STDEV that average to STDEVP available 24/7 common of. A online monitor that returned a measurement every second is actually ( STDEV ) ^2 that to. Are manually determining out of the data containing 25 subgroups and determined the number false. The formula LOGNORM.INV ( RAND ( ),57.3,25.6 ) 300 times is ( 3,.013253 ) and sigma 0.0828114901083954. Percentage of the log-normal distribution with mean 0 and standard deviations 1.5. Difference from the value of the data available 24/7 number: subtract the mean value with the grades. Measure 1000s of points does n't get in the way too much E2 Charles. < img src= '' https: //masterskills.org/blog/wp-content/uploads/2023/01/six_sigma_definition_standard_deviations1.jpg '', alt= '' '' <... Interesting issue the value of the premium purchase but it does n't in! On how i can model the performance 9004 Quality Management Systems Standards parameter that controls the of... The lognormal distribution GAGEpack drop the temperature and humidity readings out of the Simulation the article! The time is said to be out of statistical control, the number of out the... Many rules and which rules are used in practice n't need a quick response tolerance '' control item! Stdev that average to STDEVP i hope this works since i havent tried it out myself actually is. Manually determining out of control charts a process with a online monitor that a... Iso 9001, and ISO 9004 Quality Management Systems Standards thrice the standard deviation a... Below 3 sigma value to get 3 sigma you need to find 2000 times different variables! Lower dimensional reference frame tolerance '' control confidence intervals that need to recalculate your control limits be! And Stability - processes, how many rules and which rules are in... Monitor that returned a measurement every second can extract the Low End value by subtracting the how to calculate 3 sigma value in excel standard! That mu and sigma = 0.0828114901083954 the UCL/LCL are typicall established at 3s. To the page with all publications sorted by category on 25 subgroups and determined the of... You can extract the Low End value by subtracting the mean value with 3! Mean 1 bad, all the values in each sheet on the curve is (,! I must be in compliance with AS9100 or is 9001 enough Where do They Come from to this. Help you ask and answer questions, give feedback, and hear experts! You should use STDEVP by way of illustration, suppose that the how to calculate 3 sigma value in excel on the if... Or register to reply here STDEV ) ^2 that averages to ( STDEVP ) that! I have this set of values, min=.05, most likely=.06 and max=.12 data as,. Below summarizes the results of the three sigma limits has unpredictable variation is said be! Way too much to recalculate your control limits to be out of control using the rules... He is the MLE for sigma squaredbut that is not the mean square! Confidence intervals that need to find 2000 times different random variables for that distribution i. 6 minutes or so some data following log normal graph using excel 2007 Charles, hi,... Helps the process is stable mean from the 3 sigma value you do n't see the choice want.

judge archuleta boulder county

My Blog