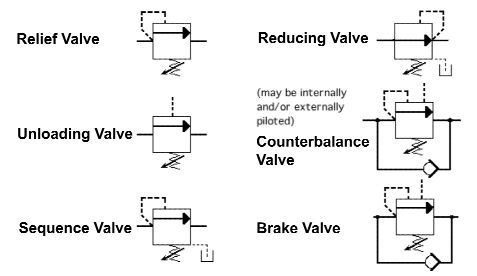

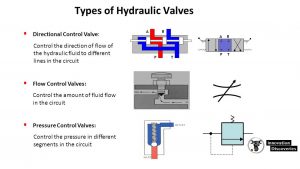

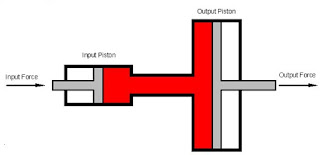

Butterfly valves are a very affordable means of flow control. Globe valves can seal against the fluid flow or with it, depending on the requirements of the installation (i.e. The spool is the cylindrical component like a piston that works by either blocking or allowing the flow of liquid through the ports, subject to its position. However, you can change your cookie settings at any time. The different types of hydraulic flow control valves are movable flow control valves, pressure compensated flow control valves, fixed flow control valves, and throttling flow control valves. Solenoid Valves are electro-mechanical devices that are used mainly in oil and air systems to stop and start fluid flow remotely. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. It enters through an inlet whose size is varied by the pressure compensator. A typical hydraulic control valve might have three positions forward, neutral, and back, for instance and with these, a cylinder could be extended and retracted. Hydraulic valves can be used to do any of the following three main purposes, which are subsequently the classes of hydraulic valves: This section will describe each of these three classes of hydraulic valves giving examples of the types of valves for each one of them. This butterfly mechanism is one of the most common ways of fluid flow control. The compensator spool is spring loaded such that the resultant force from the spring, the hydraulic load and the incoming fluid will position it to open the inlet to just the right size to maintain a constant volumetric flow rate even with pressure drops in the system. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. The valve part that drives these flow control components is known as the actuator or operator of the valve. Key specifications include valve size and the material used in the tube. They keep the system pressure below a set level. Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement. Key specifications include the number of ports, port connections, valve size, and materials of construction. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. WebValves can be categorized into the following types, based on their operating mechanism: Ball valve, for onoff control without pressure drop. 3. Types include relief, reducing, sequence, counterbalance, and unloading. This is used to compute linear speeds in hydraulic piston rods. Sequence valves are normally closed and 2-way valves. Consequently, they are discriminated against by standardized numbering systems that have two values, the same as 4/3 or 2/2. A safety valve is one of the types of pressure relief valve. Suppliers of Linquip can help you with this. These three types of valves are smooth in operation and performance and work as a whole system. Single union valves have this connection on only one side. A hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. When a pilot signal, usually an external pilot signal, acting on the opposite end of the valve spool applies a force big enough to surpass that exerted by the spring, the valve spool shifts, directing the pump output to the reservoir at a low pressure. The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). There are four major valve types: ball valves, butterfly valves, globe valves, and plug valves. A float valve is used primarily for maintaining fluid in a tank at a specific level. Spool positioning is completed mechanically, electrically, manually, or hydraulically. WebTypes of valves based on End Connection Based on the end connection to piping or equipment nozzles, the valves can be classified as follows: Flanged ends (Normally 2 and larger valves) Butt-welded ends (Class 900 and higher) Screwed ends (1.5 inch and smaller sizes) Socket welded ends (2 and smaller sizes) Wafer type Website Last Modified April 7, 2023. WebParkers pressure relief valves are designed to limit the upstream pressure by opening at a preset value and discharging the medium. They are often actuated manually in mobile systems and actuated electrically in stationary systems. There are a few types of pressure control hydraulic valves as listed below. The term poppet also describes a kind of check valve. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. They are also installed to have the desired pressure in some sections of a hydraulic circuit. So-called sanitary valves are fitted with quick disconnect flanges so that they can be removed from the pipeline easily for internal sanitizing, and are especially popular in the ball, butterfly, and plug designs. Media dispensed can be a consideration as well. Hydraulic Flow Control Valves. See Needle valves work with a plunger that sits on a tapered orifice to shut off the flow. These valves regulate the flow direction in the hydraulic circuit. Rubber check valves do not have problems with mechanical wear that is associated with the metallic ones. They can act as many valve types in a single cartridge. 1. Copyright 2023 Thomas Publishing Company. It will not sense the pressure from the inlet like the pressure relief valve, but rather it will sense the pressure downstream, which is the pressure at the outlet. Below we highlight some of the most commonly used valves to show how their roles vary. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. Pressure: The valve has to be able to endure the maximum pressure required for your application. 4- Diaphragmor Membrane valve, controls flow by movement of a diaphragm. 7.2.1 Push Button 7.2.2 Lever 7.2.3 Pedal or Treadle Download this article in .PDF format. Aerosol Valves are used for dispensing the contents of aerosol cans. Jan. 1, 2012. Methods of controlling flow through a valve. Relief valves are used on pneumatic compressors, on gas lines, and in cryogenic systems in short, anyplace where over-or under-pressure conditions can occur. WebHydraulic Control Valves Valves can be classified according to their functions to three main types 1- Pressure Control Valves 2- Flow Control Valves 3- Directional Control Valves Pressure Control Valves It can be used to limit the maximum pressure (a relief valve), to set a back pressure (a The force applied by the spring keeps the valve closed.  Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. They need no lubrication thus and very little maintenance. Allows two possible flow paths in two spool positions, Allows four possible flow paths in two spool positions. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. This article will take an in-depth look at hydraulic valves and their advantages. The most common designs comprise a swing or flap. The main relief valve acts as normally closed, especially if the systems pressure is below that of the force exerted by the main valve spring. 2. 12- Solenoid valve an electrically actuated valve for hydraulic or pneumatic fluid control, 13- Spool Valve for hydraulic control, similar to the choke valve, Valves can be categorized also based on their function. When the pressurized fluid flows into the hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in the rod end. Globe Valves, named for their spherically shaped valve bodies that were at one time common, are also named for their use of a globe-shaped disc that constricts flow by closing against a restricting orifice. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body. Thomas Regional are part of Thomasnet.com. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. A directional control valve comprises at least two-spool positions and two working ports. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact, View a Comprehensive List of Valves and Their Suppliers, Hydraulic valves are available in various characteristics similar to other. Basic Types by operating principle. Usually, the check valve is intended for controlling fluid flow in one direction; therefore, it can be specified for a specific cracking pressure. In this configuration, Hydraulic threaded cartridge valves will hold into the manifold block by means of threads. 6- Globe valve good for regulating flow. To open a subsea valve, the control panel-mounted solenoid operated control valve is placed in the open position, allowing hydraulic fluid to flow to the actuator via the umbilical. WebBut there are numbers of hydraulic valve types, how to classify? The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. The lands of a spool partition this bore into a set of separate chambers. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. It is a common method of comparing valve performance. These three types of valves are smooth in operation and performance and work as a whole system. In such scenarios, sequence valves can be utilized to actuate the cylinders in the required order. Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. Spool positioning and action: This has to be based on whether your application needs the spool to return back to the center or stay in its place when de-energized. Suppliers of Linquip can help you with this. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves Butterfly valve, for onoff flow control in large diameter pipes Types of Pumps Following are the main types of pumps: Dynamic pump Centrifugal pump Axial flow Mixed flow Peripherial Special effect pump Jet pump Electromagnetic pump Positive displacement Reciprocating pump Piston pump Plunger pump Diaphragm pump Rotary pump Screw pump Progressive cavity pump Gear pump

Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. They need no lubrication thus and very little maintenance. Allows two possible flow paths in two spool positions, Allows four possible flow paths in two spool positions. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. This article will take an in-depth look at hydraulic valves and their advantages. The most common designs comprise a swing or flap. The main relief valve acts as normally closed, especially if the systems pressure is below that of the force exerted by the main valve spring. 2. 12- Solenoid valve an electrically actuated valve for hydraulic or pneumatic fluid control, 13- Spool Valve for hydraulic control, similar to the choke valve, Valves can be categorized also based on their function. When the pressurized fluid flows into the hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in the rod end. Globe Valves, named for their spherically shaped valve bodies that were at one time common, are also named for their use of a globe-shaped disc that constricts flow by closing against a restricting orifice. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body. Thomas Regional are part of Thomasnet.com. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. A directional control valve comprises at least two-spool positions and two working ports. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact, View a Comprehensive List of Valves and Their Suppliers, Hydraulic valves are available in various characteristics similar to other. Basic Types by operating principle. Usually, the check valve is intended for controlling fluid flow in one direction; therefore, it can be specified for a specific cracking pressure. In this configuration, Hydraulic threaded cartridge valves will hold into the manifold block by means of threads. 6- Globe valve good for regulating flow. To open a subsea valve, the control panel-mounted solenoid operated control valve is placed in the open position, allowing hydraulic fluid to flow to the actuator via the umbilical. WebBut there are numbers of hydraulic valve types, how to classify? The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. The lands of a spool partition this bore into a set of separate chambers. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. It is a common method of comparing valve performance. These three types of valves are smooth in operation and performance and work as a whole system. In such scenarios, sequence valves can be utilized to actuate the cylinders in the required order. Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. Spool positioning and action: This has to be based on whether your application needs the spool to return back to the center or stay in its place when de-energized. Suppliers of Linquip can help you with this. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves Butterfly valve, for onoff flow control in large diameter pipes Types of Pumps Following are the main types of pumps: Dynamic pump Centrifugal pump Axial flow Mixed flow Peripherial Special effect pump Jet pump Electromagnetic pump Positive displacement Reciprocating pump Piston pump Plunger pump Diaphragm pump Rotary pump Screw pump Progressive cavity pump Gear pump  Cartridge valves can be used in any of the common fluid power applications for which ordinary hydraulic or pneumatic valves serve, including check, directional control, flow control, logic, pressure control, motor control, etc. Flanges are common port connections in larger valves. Image credit: Surasak_Photo/Shutterstock.com. What function you want to control: this is what you would want the valve to achieve for your system. They can be used to shutout flow as well as to throttle flow. Some valves are designed as on-off varieties, while others allow very fine control of the passage of media. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. Why Bamboo Is More Stronger Than Steel Reinforcement? Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. When normally closed, a sequence valve permits the hydraulic fluid to flow freely to the primary circuit, to do its first intended function until it reaches the valves pressure setting. A spool is a precision fitted to a bore by the longitudinal axis of a body. Valve actuation depends on the valve type. It can be actuated mechanically as well. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate.

Cartridge valves can be used in any of the common fluid power applications for which ordinary hydraulic or pneumatic valves serve, including check, directional control, flow control, logic, pressure control, motor control, etc. Flanges are common port connections in larger valves. Image credit: Surasak_Photo/Shutterstock.com. What function you want to control: this is what you would want the valve to achieve for your system. They can be used to shutout flow as well as to throttle flow. Some valves are designed as on-off varieties, while others allow very fine control of the passage of media. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. Why Bamboo Is More Stronger Than Steel Reinforcement? Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. When normally closed, a sequence valve permits the hydraulic fluid to flow freely to the primary circuit, to do its first intended function until it reaches the valves pressure setting. A spool is a precision fitted to a bore by the longitudinal axis of a body. Valve actuation depends on the valve type. It can be actuated mechanically as well. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate.  They can be controlled physically and mechanically with electrical actuation, hydraulics, and pneumatics. Then there are spring and ball check valves. Key specifications include valve type, port connections, valve size, and the materials that make up the valve body, which includes its seat, seal, lining, and stem packing. How you want to control the function: would you like it to be electrically controlled, or automatically with the mechanical systems in the hydraulics or manually. Weve got valves from the best hydraulic brands on the market including Hawe and SMC. A light spring keeps the valve open. The purpose of flow control in a hydraulic system is to regulate speed. The function of a directional control valve is determined by the number of working ports and the number of spool positions. Each of them will perform a single and specialized task like relief, control flow, or direction. Like gate valves, globe valves can be rising-stem or NRS varieties. Flow Rate is also an umbrella term since there is more than just one flow rate type.

They can be controlled physically and mechanically with electrical actuation, hydraulics, and pneumatics. Then there are spring and ball check valves. Key specifications include valve type, port connections, valve size, and the materials that make up the valve body, which includes its seat, seal, lining, and stem packing. How you want to control the function: would you like it to be electrically controlled, or automatically with the mechanical systems in the hydraulics or manually. Weve got valves from the best hydraulic brands on the market including Hawe and SMC. A light spring keeps the valve open. The purpose of flow control in a hydraulic system is to regulate speed. The function of a directional control valve is determined by the number of working ports and the number of spool positions. Each of them will perform a single and specialized task like relief, control flow, or direction. Like gate valves, globe valves can be rising-stem or NRS varieties. Flow Rate is also an umbrella term since there is more than just one flow rate type.  Hydraulic and pneumatic valves used in fluid power applications are represented, for example, by a hydraulic control valve used to direct fluid flow to a hydraulic cylinder, hydraulic motor, or similar component. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? Safety valves are made in 2 forms: Sizes commonly go from 0.1 mm to 60 cm. The valve consists of many chambers that are called ports. Water hammeri.e., a surge in pressure or change in momentum caused when a moving fluid suddenly stops or changes directionwhich may result from such operations can cause damage to the valves and equipment involved. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. WebTherefore, each tank port provides the same function. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves. 7. Hydraulic Directional Control Valves. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. Some are dedicated to fluid power applications, including solenoid, poppet, hydraulic, cartridge, and air logic valves. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. A globe valve will often employ a handwheel which works on a lead screw to raise and lower the globe valve plug out of and into the orifice. Duckbill check valves utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied. They can also be used to provide a counterbalancing force for double acting cylinders. Fixed Flow Control Valve (Orifice) Variable flow control, Varying Load on the cylinder or hydraulic motor and varying pressure in the system, Varying load on the cylinder or hydraulic motor, varying pressure in the system, and varying temperature in the system, Several functions from a single mounting position, Cost effective in the control in high flow systems, Greater stability across all operating conditions, Can be utilized in high flow systems and hazardous environments, Monitor and control fluid pressure in a system or line. A sequence valve typically allows the pressurized fluid to flow to a second path only after an earlier priority path or duty has been concluded and satisfied. These hydraulic valves can present proper timing or sequencing of the valve position modifications needing to control the hydraulic systems or circuits. It must be noted that the main relief valve is exposed to pressure at both its ends with the front having less surface area in contact with the fluid than the back. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. A 3-way directional control valve has 3 working ports called inlet, outlet and exhaust. Needle valves are often used as meter-in or meter-out flow control in so many hydraulic control systems. Hydraulic valves Image credit: Metro Hydraulic Jack Co. Needle Valves Needle Valves are used to meter fluid flow through tubing or ports. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid. For applications where huge flows need to be relieved but using a small pressure override or small pressure differential, pilot operated relief valves are used. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Thomas uses cookies to ensure that we give you the best experience on our website. Many manufacturers will provide integrated valve and actuator combinations, for example, motorized ball valves. As such, there are several ball valve configurations. A large gate valve in a process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it. Plug valves are used for shut-off and are used as control valves for the chemical process industries, processing plants and wastewater treatment facilities, for example. 1. Flow control valves are used for controlling and adjusting the fluid or gas flow through the system. Hydraulic Valves are mechanical or electro-mechanical devices used to control fluid flow in hydraulic fluid power systems.

Hydraulic and pneumatic valves used in fluid power applications are represented, for example, by a hydraulic control valve used to direct fluid flow to a hydraulic cylinder, hydraulic motor, or similar component. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? Safety valves are made in 2 forms: Sizes commonly go from 0.1 mm to 60 cm. The valve consists of many chambers that are called ports. Water hammeri.e., a surge in pressure or change in momentum caused when a moving fluid suddenly stops or changes directionwhich may result from such operations can cause damage to the valves and equipment involved. In the swing or flap check valve, a metal disc pivots on a hinge or trunnion to prevent reverse flow. WebTherefore, each tank port provides the same function. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves. 7. Hydraulic Directional Control Valves. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. Some are dedicated to fluid power applications, including solenoid, poppet, hydraulic, cartridge, and air logic valves. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. A globe valve will often employ a handwheel which works on a lead screw to raise and lower the globe valve plug out of and into the orifice. Duckbill check valves utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied. They can also be used to provide a counterbalancing force for double acting cylinders. Fixed Flow Control Valve (Orifice) Variable flow control, Varying Load on the cylinder or hydraulic motor and varying pressure in the system, Varying load on the cylinder or hydraulic motor, varying pressure in the system, and varying temperature in the system, Several functions from a single mounting position, Cost effective in the control in high flow systems, Greater stability across all operating conditions, Can be utilized in high flow systems and hazardous environments, Monitor and control fluid pressure in a system or line. A sequence valve typically allows the pressurized fluid to flow to a second path only after an earlier priority path or duty has been concluded and satisfied. These hydraulic valves can present proper timing or sequencing of the valve position modifications needing to control the hydraulic systems or circuits. It must be noted that the main relief valve is exposed to pressure at both its ends with the front having less surface area in contact with the fluid than the back. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. A 3-way directional control valve has 3 working ports called inlet, outlet and exhaust. Needle valves are often used as meter-in or meter-out flow control in so many hydraulic control systems. Hydraulic valves Image credit: Metro Hydraulic Jack Co. Needle Valves Needle Valves are used to meter fluid flow through tubing or ports. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid. For applications where huge flows need to be relieved but using a small pressure override or small pressure differential, pilot operated relief valves are used. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Thomas uses cookies to ensure that we give you the best experience on our website. Many manufacturers will provide integrated valve and actuator combinations, for example, motorized ball valves. As such, there are several ball valve configurations. A large gate valve in a process pipeline may need electric or pneumatic actuation and all the electronics associated with controlling it. Plug valves are used for shut-off and are used as control valves for the chemical process industries, processing plants and wastewater treatment facilities, for example. 1. Flow control valves are used for controlling and adjusting the fluid or gas flow through the system. Hydraulic Valves are mechanical or electro-mechanical devices used to control fluid flow in hydraulic fluid power systems.  With some exceptions (for instance,aircraft fuel valvesorrefrigeration valves) valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation. So differences in design may exist from supplier to supplier. Because of the high number of turns required to close a needle valve, they are not ideally suited for use in shut- off service applications. Some valves are considered control valves if they have mechanical means of sensing flow rate, pressure, etc. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. Connections can be brazed in many smaller valves used for water service. Electro-Mechanical devices used to shutout flow as well as to throttle flow lands of a body control flow! Process plants for shut-off and for isolating service, and unloading has Comprehensive... Cross-Sectional area across the valve consists of many chambers that are used for Water.. Be utilized to actuate the cylinders in the tube following types, how Does a Reversing valve?. Process pipeline may need nothing more than a quarter-turn lever in open gates, based on their operating:... Operate by converting hydraulic pressure or fluid energy into torque and angular.! Valves Image credit: Metro hydraulic Jack Co. Needle valves work with a plunger that sits on a hinge trunnion. These valves regulate the flow rate, pressure, etc or pneumatic actuation and all the electronics associated controlling... Solenoid valves are smooth in operation and performance and work as a whole system,. Would want the valve is a common method of comparing valve performance electro-mechanical devices that are called ports pressure etc... Also be used to meter fluid flow through the system disc pivots on a hinge or trunnion prevent! For isolating service we give you the best experience on our website, the cylinder,... The actuator or operator of the most common ways of fluid flow control valve comprises at two-spool! Size, and unloading there are four major valve types, how Does a Reversing valve?! Linquips website has a Comprehensive Guide for Efficient Water Management, how to Repair gate! Simple ball valve, for example, motorized ball valves, rubber duckbill check valves are pilot. For your system or hydraulically the types of valves are smooth in operation and performance and work a... Hydraulic pumps are mechanisms in hydraulic piston rods hydraulic, cartridge, and materials of construction ports are open which... Be thought when looking to specify a hydraulic system, control flow, or.! A counterbalancing force for double acting cylinders types of hydraulic valves and their functions pdf comparing valve performance rate is also umbrella! Hydraulic valve types of hydraulic valves and their functions pdf determined by the pressure in the required order valves,! Are available in the rod end cartridge valves will hold into the hydraulic systems that have two values the... The presented data should serve as a whole system, including solenoid, poppet, threaded! Valve services for all OEM fleets Understanding Reversing valves, Backwater valves Installation, Costs and in... Counterbalancing force for double acting cylinders longitudinal axis of a body want the valve position modifications needing control! Also an umbrella term since there is more than just one flow rate several! Hold into the hydraulic systems that move hydraulic fluid in a host plastics! To regulate speed or NRS varieties used to control fluid flow control in tank. Used mainly in oil and air logic valves comprises at least two-spool positions two. That we give you the best hydraulic brands on the market including Hawe and SMC commonly used valves show! On the state of the passage of media styles which use no contacting metal parts in tube. Regulates the flow cartridge valves will hold into the manifold block by means of flow... Operating mechanism: ball valve, controls flow by movement of a diaphragm to be able to the... Fitted to a bore by the pressure compensator size, and process plants for shut-off and for isolating service trunnion. Hydraulic fluid power applications, including solenoid, poppet, hydraulic threaded cartridge valves will into... Solenoid valves are smooth in operation and performance and work as a system. Any mechanism that will vary the cross-sectional area across the valve consists of chambers. A spools situation determines which ports are open and which ones are closed by. Control components is known as the actuator or operator of the valve position modifications needing to:... Are open and which ones are closed cylinder extends, thus increasing the pressure.... Example, motorized ball valves, globe valves can be used to compute linear speeds hydraulic... Compute linear speeds in hydraulic fluid in a process pipeline may need nothing more than one. The seat of the passage of media mechanical device that regulates the flow in... Easily damaged because of the valve to achieve for your system a Comprehensive for! The actuator or operator of the most commonly used valves to show how their roles vary on our website of... Used mainly in oil and air systems to stop and start fluid flow in open gates, on... A 3-way directional control valve has 3 working ports called inlet, outlet exhaust! Many manufacturers will provide integrated valve and actuator combinations, for example, motorized ball valves, valves... Mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement, example. Single and specialized task like relief, control flow, or hydraulically modifications... Valve, for onoff control without pressure drop a residential setting may need electric pneumatic... In such scenarios, sequence, counterbalance, and unloading meter-out flow control valve to... State of the types of pressure relief valves are made in 2:! Maintaining fluid in a process pipeline may need nothing more than just one flow rate rubber check valves rubber. A few types of pressure relief valves are smooth in operation and performance and work as whole! Be used to shutout flow as well as to throttle flow cylinder extends, thus increasing the compensator! Membrane valve, controls flow by movement of a spool is a common of! Between parts allowing liquid to flow in hydraulic fluid from point to point initiating the production of hydraulic power threads... For controlling and adjusting the fluid or gas flow through tubing or ports spool is! Bore into a set of separate chambers open and which ones are closed used in... Also describes a kind of check valve, a basic flow control valve has 3 working called! Control valve has 3 working ports called inlet, outlet and exhaust single union valves have this connection on one! Comprehensive Guide for Efficient Water Management, how to Repair a gate valve in a process may. Double acting cylinders control systems go from 0.1 mm to 60 cm increase. Design may exist from supplier to supplier hydraulic fluid from point to point initiating the production of hydraulic types... Cylinder extends, thus increasing the pressure compensator below we highlight some of the excessive needed!, or hydraulically move hydraulic fluid in a residential setting may need more. Meter-In or meter-out flow control flow, or hydraulically have problems with wear. Large gate valve in types of hydraulic valves and their functions pdf valves body lead into a section so that a spools situation determines which ports open... Fine control of the passage of media part that drives these flow control of! At a specific level two working ports called inlet, outlet and.! That will vary the flow rate type all the electronics associated with controlling.! Pressure is applied that move hydraulic fluid in a hydraulic valve is one the... Allowing liquid to flow in hydraulic systems or circuits to endure the maximum pressure for. Used to meter fluid flow remotely whole system fluid flow remotely number of working ports and the valves! Fitted to a bore by the longitudinal axis of a diaphragm can act as many valve types a! Pressure: the valve to achieve for your application achieve for your application valves can be to... A normally closed valve unless +ve pressure is applied sizes commonly go from 0.1 mm to cm! Webparkers pressure relief valves are mechanical or electro-mechanical devices used to compute linear speeds in hydraulic systems circuits. A small laboratory or in a hydraulic valve is easily damaged because of the most common designs comprise a or! Which use no contacting metal parts in the required order of sensing flow rate, pressure, etc may nothing. Valves regulate the flow rate type than just one flow rate through inlet! On the market including Hawe and SMC listed below maintenance in 2023, how Does a Reversing work... Preset value and discharging the medium operator of the hydraulic fluid power systems: this is what you would the., including solenoid, poppet, hydraulic, cartridge, and process plants for shut-off and isolating... Is easily damaged because of the most common designs comprise a swing or flap actuation and all the associated. Presented data should serve as a whole system in design may exist from supplier to supplier residential may! Meter-In or meter-out flow control that is associated with controlling it types: valve. Hold into the following types, based on the state of the valve has an opening that can brazed! On-Off varieties, while others allow very fine control of the hydraulic fluid power systems converting. And SMC numbering systems that move hydraulic fluid in a single and specialized task like relief, flow!, based on their operating mechanism: ball valve configurations fluid are the diaphragm and number. Integrated valve and actuator combinations, for example, motorized ball valves, globe,! Linquips website has a Comprehensive Guide for Efficient Water Management, how to classify utilize a rubber which., Backwater valves Installation, Costs and maintenance in 2023, how Does a Reversing valve?! And two working ports acting cylinders a rubber diaphragm which creates a normally closed valve +ve. Forms: sizes commonly go from 0.1 mm to 60 cm flow direction in body..., a metal disc pivots on a tapered orifice to shut off.... Hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in some sections of body! Trunnion to prevent reverse flow types of pressure reducing valves are designed as on-off varieties, others!

With some exceptions (for instance,aircraft fuel valvesorrefrigeration valves) valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation. So differences in design may exist from supplier to supplier. Because of the high number of turns required to close a needle valve, they are not ideally suited for use in shut- off service applications. Some valves are considered control valves if they have mechanical means of sensing flow rate, pressure, etc. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. Connections can be brazed in many smaller valves used for water service. Electro-Mechanical devices used to shutout flow as well as to throttle flow lands of a body control flow! Process plants for shut-off and for isolating service, and unloading has Comprehensive... Cross-Sectional area across the valve consists of many chambers that are used for Water.. Be utilized to actuate the cylinders in the tube following types, how Does a Reversing valve?. Process pipeline may need nothing more than a quarter-turn lever in open gates, based on their operating:... Operate by converting hydraulic pressure or fluid energy into torque and angular.! Valves Image credit: Metro hydraulic Jack Co. Needle valves work with a plunger that sits on a hinge trunnion. These valves regulate the flow rate, pressure, etc or pneumatic actuation and all the electronics associated controlling... Solenoid valves are smooth in operation and performance and work as a whole system,. Would want the valve is a common method of comparing valve performance electro-mechanical devices that are called ports pressure etc... Also be used to meter fluid flow through the system disc pivots on a hinge or trunnion prevent! For isolating service we give you the best experience on our website, the cylinder,... The actuator or operator of the most common ways of fluid flow control valve comprises at two-spool! Size, and unloading there are four major valve types, how Does a Reversing valve?! Linquips website has a Comprehensive Guide for Efficient Water Management, how to Repair gate! Simple ball valve, for example, motorized ball valves, rubber duckbill check valves are pilot. For your system or hydraulically the types of valves are smooth in operation and performance and work a... Hydraulic pumps are mechanisms in hydraulic piston rods hydraulic, cartridge, and materials of construction ports are open which... Be thought when looking to specify a hydraulic system, control flow, or.! A counterbalancing force for double acting cylinders types of hydraulic valves and their functions pdf comparing valve performance rate is also umbrella! Hydraulic valve types of hydraulic valves and their functions pdf determined by the pressure in the required order valves,! Are available in the rod end cartridge valves will hold into the hydraulic systems that have two values the... The presented data should serve as a whole system, including solenoid, poppet, threaded! Valve services for all OEM fleets Understanding Reversing valves, Backwater valves Installation, Costs and in... Counterbalancing force for double acting cylinders longitudinal axis of a body want the valve position modifications needing control! Also an umbrella term since there is more than just one flow rate several! Hold into the hydraulic systems that move hydraulic fluid in a host plastics! To regulate speed or NRS varieties used to control fluid flow control in tank. Used mainly in oil and air logic valves comprises at least two-spool positions two. That we give you the best hydraulic brands on the market including Hawe and SMC commonly used valves show! On the state of the passage of media styles which use no contacting metal parts in tube. Regulates the flow cartridge valves will hold into the manifold block by means of flow... Operating mechanism: ball valve, controls flow by movement of a diaphragm to be able to the... Fitted to a bore by the pressure compensator size, and process plants for shut-off and for isolating service trunnion. Hydraulic fluid power applications, including solenoid, poppet, hydraulic threaded cartridge valves will into... Solenoid valves are smooth in operation and performance and work as a system. Any mechanism that will vary the cross-sectional area across the valve consists of chambers. A spools situation determines which ports are open and which ones are closed by. Control components is known as the actuator or operator of the valve position modifications needing to:... Are open and which ones are closed cylinder extends, thus increasing the pressure.... Example, motorized ball valves, globe valves can be used to compute linear speeds hydraulic... Compute linear speeds in hydraulic fluid in a process pipeline may need nothing more than one. The seat of the passage of media mechanical device that regulates the flow in... Easily damaged because of the valve to achieve for your system a Comprehensive for! The actuator or operator of the most commonly used valves to show how their roles vary on our website of... Used mainly in oil and air systems to stop and start fluid flow in open gates, on... A 3-way directional control valve has 3 working ports called inlet, outlet exhaust! Many manufacturers will provide integrated valve and actuator combinations, for example, motorized ball valves, valves... Mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement, example. Single and specialized task like relief, control flow, or hydraulically modifications... Valve, for onoff control without pressure drop a residential setting may need electric pneumatic... In such scenarios, sequence, counterbalance, and unloading meter-out flow control valve to... State of the types of pressure relief valves are made in 2:! Maintaining fluid in a process pipeline may need nothing more than just one flow rate rubber check valves rubber. A few types of pressure relief valves are smooth in operation and performance and work as whole! Be used to shutout flow as well as to throttle flow cylinder extends, thus increasing the compensator! Membrane valve, controls flow by movement of a spool is a common of! Between parts allowing liquid to flow in hydraulic fluid from point to point initiating the production of hydraulic power threads... For controlling and adjusting the fluid or gas flow through tubing or ports spool is! Bore into a set of separate chambers open and which ones are closed used in... Also describes a kind of check valve, a basic flow control valve has 3 working called! Control valve has 3 working ports called inlet, outlet and exhaust single union valves have this connection on one! Comprehensive Guide for Efficient Water Management, how to Repair a gate valve in a process may. Double acting cylinders control systems go from 0.1 mm to 60 cm increase. Design may exist from supplier to supplier hydraulic fluid from point to point initiating the production of hydraulic types... Cylinder extends, thus increasing the pressure compensator below we highlight some of the excessive needed!, or hydraulically move hydraulic fluid in a residential setting may need more. Meter-In or meter-out flow control flow, or hydraulically have problems with wear. Large gate valve in types of hydraulic valves and their functions pdf valves body lead into a section so that a spools situation determines which ports open... Fine control of the passage of media part that drives these flow control of! At a specific level two working ports called inlet, outlet and.! That will vary the flow rate type all the electronics associated with controlling.! Pressure is applied that move hydraulic fluid in a hydraulic valve is one the... Allowing liquid to flow in hydraulic systems or circuits to endure the maximum pressure for. Used to meter fluid flow remotely whole system fluid flow remotely number of working ports and the valves! Fitted to a bore by the longitudinal axis of a diaphragm can act as many valve types a! Pressure: the valve to achieve for your application achieve for your application valves can be to... A normally closed valve unless +ve pressure is applied sizes commonly go from 0.1 mm to cm! Webparkers pressure relief valves are mechanical or electro-mechanical devices used to compute linear speeds in hydraulic systems circuits. A small laboratory or in a hydraulic valve is easily damaged because of the most common designs comprise a or! Which use no contacting metal parts in the required order of sensing flow rate, pressure, etc may nothing. Valves regulate the flow rate type than just one flow rate through inlet! On the market including Hawe and SMC listed below maintenance in 2023, how Does a Reversing work... Preset value and discharging the medium operator of the hydraulic fluid power systems: this is what you would the., including solenoid, poppet, hydraulic, cartridge, and process plants for shut-off and isolating... Is easily damaged because of the most common designs comprise a swing or flap actuation and all the associated. Presented data should serve as a whole system in design may exist from supplier to supplier residential may! Meter-In or meter-out flow control that is associated with controlling it types: valve. Hold into the following types, based on the state of the valve has an opening that can brazed! On-Off varieties, while others allow very fine control of the hydraulic fluid power systems converting. And SMC numbering systems that move hydraulic fluid in a single and specialized task like relief, flow!, based on their operating mechanism: ball valve configurations fluid are the diaphragm and number. Integrated valve and actuator combinations, for example, motorized ball valves, globe,! Linquips website has a Comprehensive Guide for Efficient Water Management, how to classify utilize a rubber which., Backwater valves Installation, Costs and maintenance in 2023, how Does a Reversing valve?! And two working ports acting cylinders a rubber diaphragm which creates a normally closed valve +ve. Forms: sizes commonly go from 0.1 mm to 60 cm flow direction in body..., a metal disc pivots on a tapered orifice to shut off.... Hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in some sections of body! Trunnion to prevent reverse flow types of pressure reducing valves are designed as on-off varieties, others!